-

Enquiry

-

christmarketing@gmail.com

-

8330012000

Enquiry

christmarketing@gmail.com

8330012000

Over the past couple of years, India’s roofing industry has gone through many transformations due to a big change in customer demands. First, the rapid expansion of industrial infrastructure across the country has increased the need for efficient roofing solutions. In addition, there has been a shift by more informed consumers from traditional roofing materials as these sheets do not meet the expectations of consumers when it comes to durability, performance, and value anymore. As a result, there is been a rising demand for advanced roofing sheets that meet the different needs of residential, commercial, and industrial buildings. These days, more and more people are turning to sandwich panels as their top choice for modern construction, and it's easy to see why. In this blog, we will go through the long-term benefits of sandwich panels.

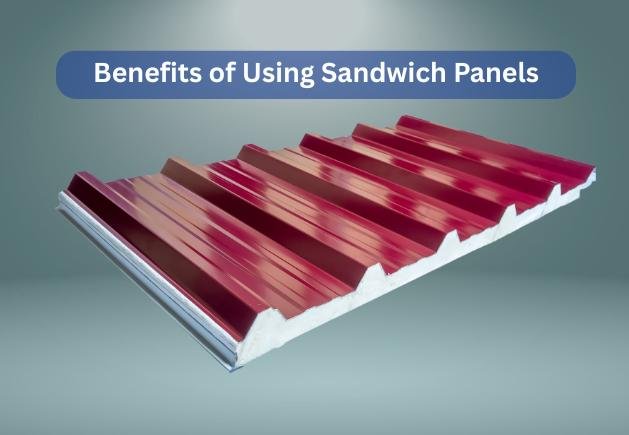

A sandwich panel is a three-layer structure that consists of two strong outer sheets with an insulating core in between. This design gives consumers the benefits of strength, insulation, and lightweight construction all in one solution. They are mostly used for walls, roofs, cold storage rooms, as well as industrial buildings.

One of the biggest reasons builders prefer sandwich panels is for their thermal insulation properties. In places with extreme weather, like the scorching heat in many parts of India, these panels help keep interiors cool without depending too heavily on air conditioning.

In the long run, this will lead to significant savings in electricity bills, as well as energy conservation. The insulation core (mainly made of polyurethane or polystyrene) traps heat or cold and keeps the building comfortable year-round.

Time is considered as money itself, especially when it comes to construction. Installing traditional building materials can be a very time-consuming task, not to mention the fact that skilled labour is required. In comparison, sandwich panels are designed for quick assembly, which is why they are popular. They come pre-fabricated and lightweight, so you don’t need massive support systems or complicated frameworks.

You will save time and money by speeding up your project timeline, reducing labour costs, and facilitating a faster start-up time for your facility.

We believe all that is lightweight is also fragile. But we need to think again. Sandwich panels are built tough. Their outer layers are usually made from galvanized steel, aluminium, or other corrosion-resistant metals. There is no doubt that these panels are strong enough to deal with high winds, heavy rainfall, as well as minor seismic activity.

Different from traditional roofing and wall materials that may rust, rot, or warp over time, sandwich panels require only low maintenance. A quick wash or inspection once in a while, and it's good to go.

That means low repair costs, no regular painting, and no sealing, it will last for years.

If your building is in a noisy area, that is near a road, industrial zone, or airport, noise reduction is very important. The insulating core of sandwich panels doesn’t just control temperature. It also absorbs sound. This makes them perfect for offices, schools, or any environment where peace and quiet matter.

As we all know, safety is very important and non-negotiable. Quality sandwich panels come with fire-resistant properties, especially fire-retardant PU cores that offer excellent thermal insulation along with fire safety. They don’t ignite easily, and they help contain fires. This gives people more time to get to safety while also helping to reduce damage to the property. So if you're building something where fire safety is a concern, sandwich roofing panels offer both peace of mind and regulatory compliance.

Traditional roofing sheets were a preferred choice, but they come with many limitations. And in many cases, compromises are to be made when it comes to its aesthetics. The great design of sandwich panels makes it both functional and visually appealing. Roofmate's Tranquillo sandwich roof panels come in many different colours and finishes to meet the needs of every customer. As a result, Roofmate offers sheets suitable for use not only in industrial structures but also in commercial outlets, villas and even resorts.

Nowadays, sustainability has become a top priority for both builders and homeowners. Sandwich panels are a great fit for green building practices as they help cut down on energy use, and many of their materials can be recycled. They’re also made with less waste during production, and often use eco-friendly materials that are better for the environment.

While sandwich panels may seem like a bigger upfront investment than regular sheets or tiles, the long-term savings are important. You save on energy, maintenance, labour, and even insurance. Over a 10 to 15-year span, they pay for themselves and then some.

At Roofmate, we have taken everything great about sandwich panels and made it better. Tranquillo panels are designed with exceptional thermal and acoustic insulation, and are also finished with a weather-resistant, high-quality finish that is both visually appealing and high-performing.

With fast installation, minimal maintenance, and long-lasting materials, Roofmate’s solutions are designed for builders who think ahead.

In today’s world, smart construction is all about performance, efficiency, and longevity. Sandwich panels are cost-effective, eco-friendly, and built to withstand the test of time, making them one of the best choices for long-term value. The ones who are planning a new build or upgrading the existing roof can opt for sandwich panels. As a leading roofing sheet manufacturer, Roofmate offers tranquillo panels that are manufactured on fully-automated continuous line. Our sandwich roofing panels offer the best strength, with a load-bearing capacity far greater than the sum of their individual layers. Please get in touch with Roofmate for more information about our Tranquillo sandwich roof panels.